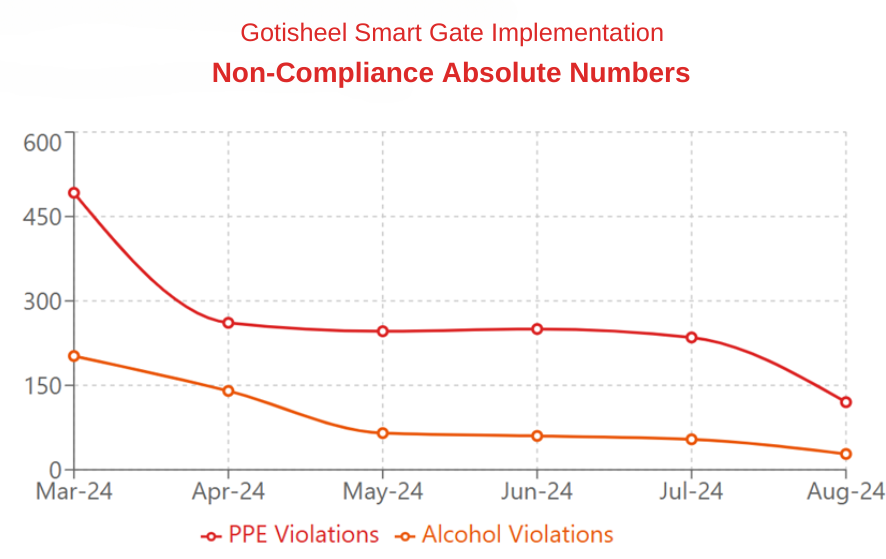

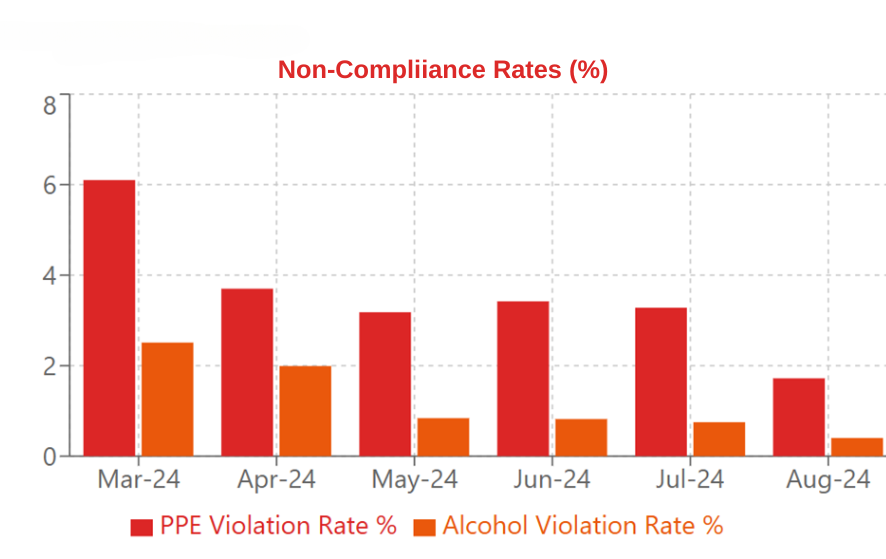

This case study examines the successful implementation of Gotisheel Technologies' Smart Access Control Solution at a prominent coal mining conglomerate. The solution transformed safety compliance monitoring and access control, resulting in a 76% reduction in PPE violations and 86% reduction in alcohol-related incidents over six months.

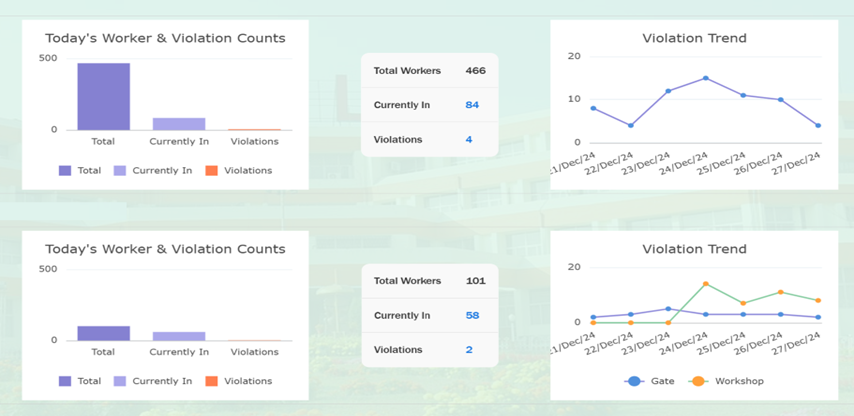

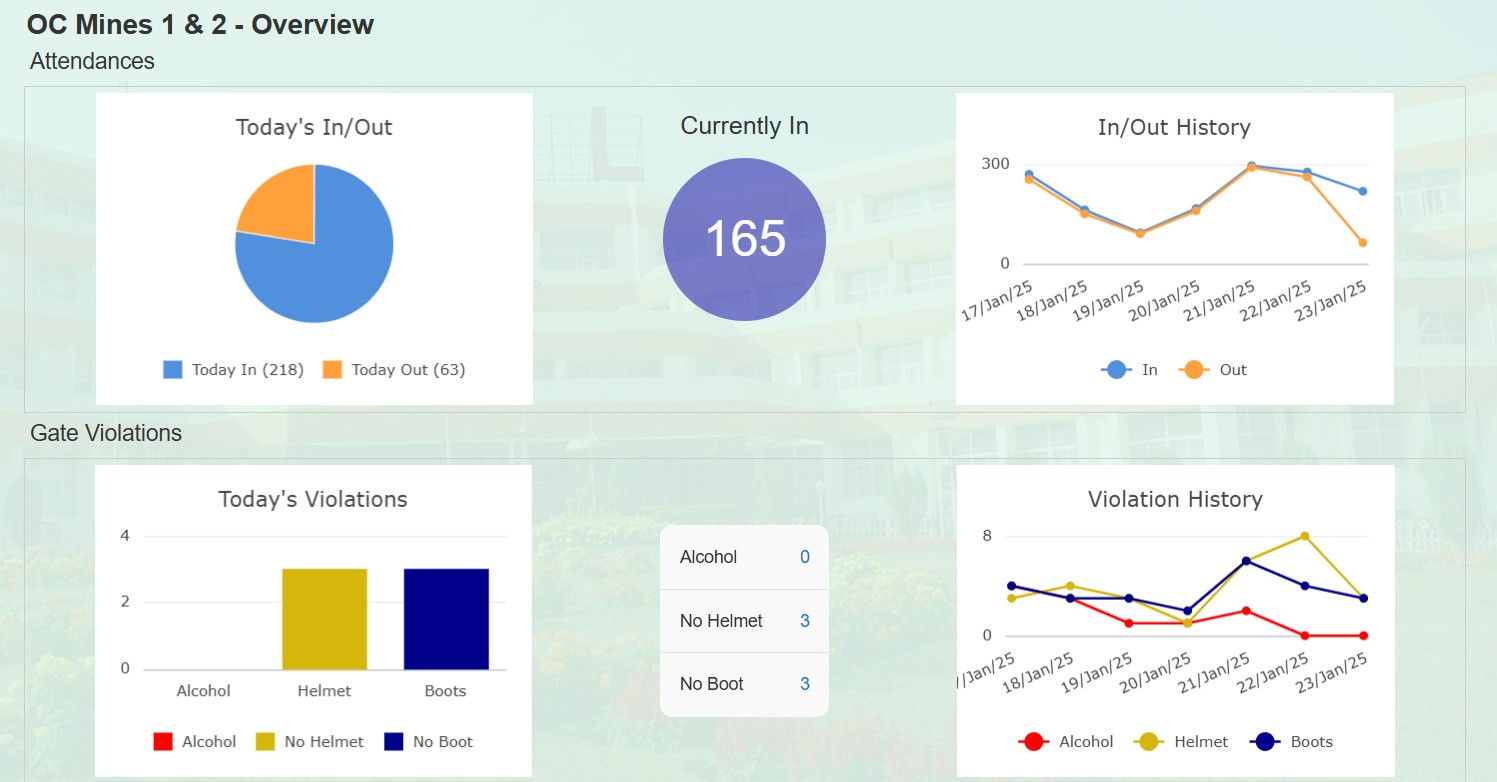

Smart gate systems with AI-based face recognition technology were fully operational at both underground mines and workshops.

Achieved 100% compliance with PPE and alcohol regulations at entry points.

Generated accurate and timely reports on personnel inside the mines and workshops. Alerts for non-returning personnel ensured quick action.

AI/ML-driven detection of violations significantly reduced non-compliance incidents.

The solution was widely appreciated within the mining community. It demonstrated how advanced technology could transform safety and compliance in hazardous work environments. The Honourable Union Minister of Coal, Government of India, highlighted and commended this solution in an official tweet, further underscoring its success and relevance.

Gotisheel Technologies' Smart Access Control Solution set a new benchmark in ensuring safety and compliance for the coal mining industry. By combining AI-driven access control, PPE enforcement, and alcohol monitoring, the solution not only mitigated risks but also showcased the transformative potential of technology in industrial safety. Gotisheel continues to drive innovation and deliver impactful solutions for industries committed to enhancing safety and operational efficiency.

Client: A leading Oil & Gas Company

Industry: Oil & Gas

Enhancing safety, streamlining operations, and ensuring regulatory compliance at an LPG Import Terminal.

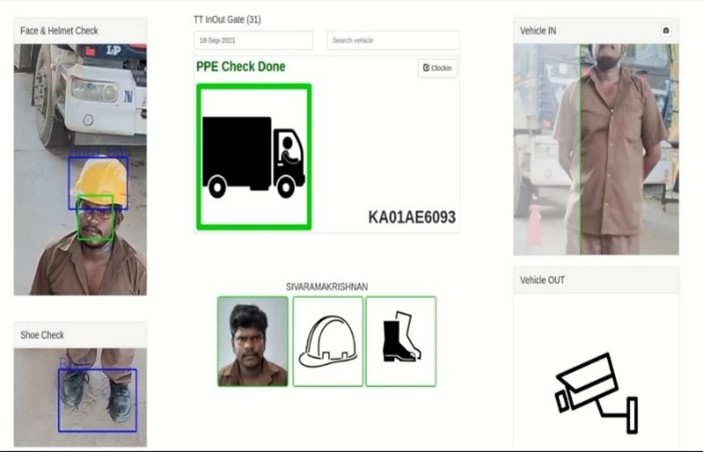

Gotisheel Technologies implemented a Smart Access Control Solution tailored to address the client’s unique challenges:

Streamlined vehicle entry/exit by automating tanker crew validation and ensuring PPE compliance.

Integrated with flap barrier gates for seamless and secure access for contract workers and tanker crew.

Automated safety training for contract workers and tanker crew, ensuring compliance and restricting invalid access.

Achieved 100% compliance with PPE and safety training requirements for hazardous areas.

Gotisheel Technologies’ Smart Access Control Solution transformed safety and compliance management at the LPG Import Terminal. The automated, AI-powered system ensured smoother operations, enhanced safety, and complete regulatory compliance, setting a new standard for safety and efficiency in the oil and gas industry.

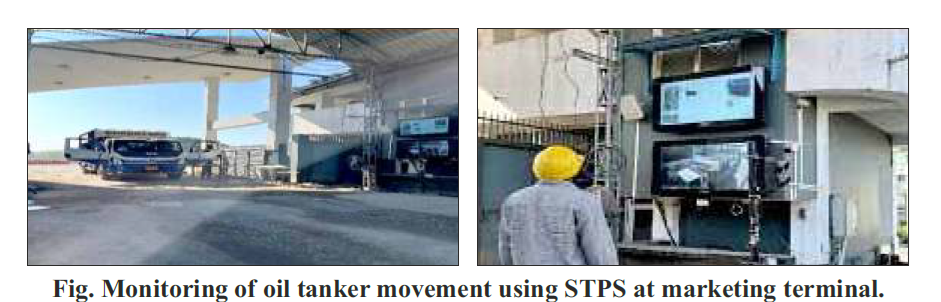

In January 2024, a major Indian oil refinery implemented Gotisheel Technologies' Smart Truck Parking and Access Control System (STPS) to address critical operational challenges in their terminal operations. The solution transformed their tank truck management system, significantly improving efficiency, safety, and transparency.

Gotisheel Technologies deployed a comprehensive STPS featuring:

The STPS solution demonstrates universal applicability across various terminal operations, making it a viable solution for any marketing terminal seeking to enhance operational efficiency and control.